Introduction to Operation Research, 10th Edition. Applied Integer Programming - Modelling and Solution. European Journal of Operational Research, Volume 262, pp.28-39, 2017. "Integer Programming Techniques for Educational Timetabling". Jurnal Optimasi Sistem Industri, Volume 15, No 2, pp.171-180, 2016. "Aplikasi Algoritma Hybrid dalam Penentuan Rute Pendistribusian Produk (Studi Kasus: PT Enseval Putera Megatrading)". Jurnal Optimasi Sistem Industri, Volume 15, No 1, pp.1-15, 2016. "Algoritma Penentuan Ukuran Batch Integer pada Penjadwalan Flowshop Satu Mesin".

Cybernetics and Information Technologies, Volume 11, No 1, pp.3-25, 2011. The latest installation package takes up 13 MB on disk.

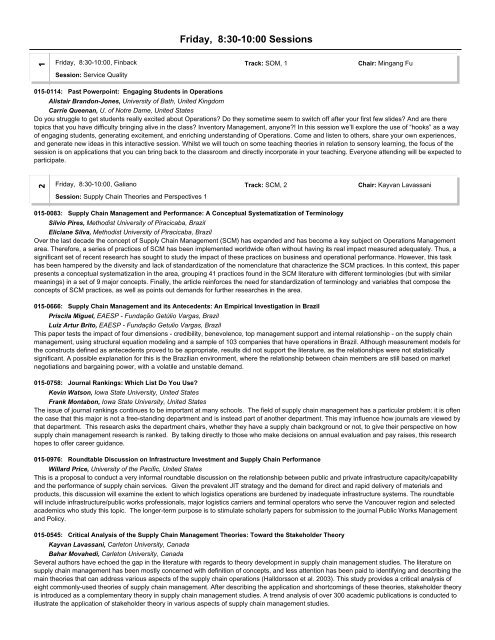

POM QM USAGE WINDOWS 10

This free PC software was developed to work on Windows XP, Windows Vista, Windows 7, Windows 8 or Windows 10 and can function on 32-bit systems. This free software is a product of Prentice-Hall Inc.

POM QM USAGE DOWNLOAD

"Linear Integer Programming Methods and Approaches – A Survey". The 5.2 version of QM for Windows is available as a free download on our software library. Linear Programming and Network Flows, 4th Edition.

Operations Research : Model-Model Pengambilan Keputusan. Integrated Production Control System: Management, Analysis, Design, 2nd Edition. Cincinati: South Western Publishing Co., 1991. Production and Inventory Management, 2nd Edition. Journal of Global Optimization, Volume 63, No 3, pp.555-582, 2014. A Hybrid Method Based on Linear Programming and Variable Neighborhood Descent for Scheduling Production in Open-pit Mines. North American Power Symposium (NAPS), Charlotte, NC, USA, 4-6 October 2015, pp.1-6. "Smart Residential Energy Scheduling Utilizing Two Stage Mixed Integer Linear Programming". Seminar Nasional Fakultas Teknik-UR, Pekanbaru, 29-30 Juni 2010, pp.1-13. Nasir, “Metode Penghematan Energi Listrik dengan Pola Pengaturan Pembebanan”. This scheduling model can decrease the penalty of electrical energy expense during PLP from Rp. The developed scheduling model has the ability to solve the problem of the “on-off” assignment for Raw Mills and Cement Mills from Indarung II to Indarung V. The decision variables are the “on-off” state of Raw Mills and Cement Mills during PLP, while the objective function is to minimize the penalty expense of energy used during PLP. To solve this problem, a scheduling model for Raw Mills and Cement Mills on-off during PLP is then developed using a linear programming approach. Meanwhile, the constraints are related to the length of machining hours of Raw Mill, Kiln or Cement Mill before preventive maintenance takes place. Those criteria refer to the achievement of daily production targets, silo content at PLP, and the requirement for particular Raw Mill or Cement Mill to be off during those 4 hours of PLP. A Raw Mill or Cement Mill can be switched-off if the specified criteria are satisfied. This regulation forces Production Department of PT Semen Padang to arrange the “on (1) or off (0)” schedule for the Raw Mills and Cement Mills during PLP. The scheduling of electrical energy usage during Peak Load Period (PLP) is a complicated problem that has been faced by PT Semen Padang after Indonesian Power Company (PLN) implemented the demarcation regulation of electrical energy usage during PLP (6:00 – 10:00 p.m.) which may not exceed 44.100 kWH.

0 kommentar(er)

0 kommentar(er)